TM 9-2320-280-20-3

I

10-66. BODY REPAIR (Cont’d)

I

(d)

(e)

(f)

(g)

(h)

Shear lock using a pin punch to drive out pin.

Pry out remainder of locking collar.

Using a drill slightly smaller than rivet shank, drill almost through rivet head.

Pry off rivet head with a pin punch.

Tap out rivet shank with a pin punch.

3. Rivnut/Plusnut Removal.

(a) Drill through rivnut head.

(b) Punch out shank.

4. Rivet Hole Drilling.

(a) Center punch all new rivet locations. Center punch mark must be large enough to prevent drill

from slipping out of position, yet it must not dent the surface of the material. To prevent denting,

place a bucking bar behind material during punching.

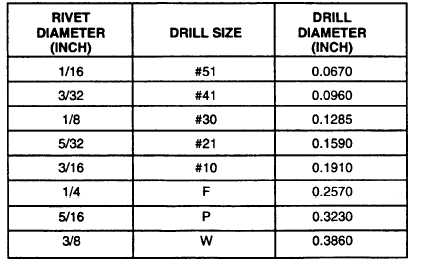

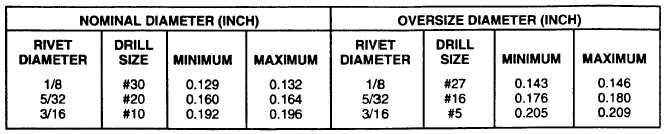

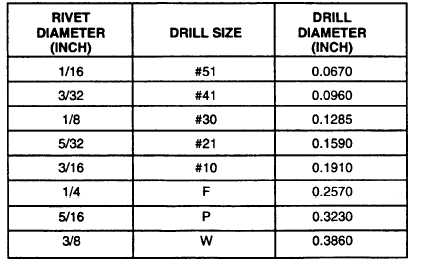

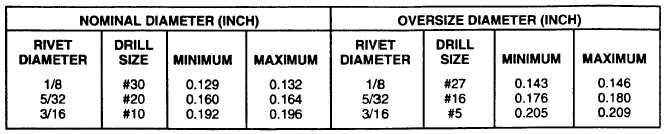

(b) Make sure drill is the correct size (tables 10-1 and 10-2) and point is properly ground. A no. 10

drill is used to install standard 3/16-inch blind rivets.

Table 10-1. Drill Sues for Solid Shank Rivets

Table 10-2. Drill Sizes for Blind Rivets

(c) Place drill in center mark for new rivet locations, or align drill with old hole when replacing old

rivets with oversize rivets. When using a power drill, give the bit a few turns with fingers before

starting motor. This will help assure that drill does not jump out of position when motor is

started.

10-107