TM 9-2320-387-24-2

I-

~~~

30-3.

DIFFERENTIAL

REPAIR (Cont’d)

I

3.

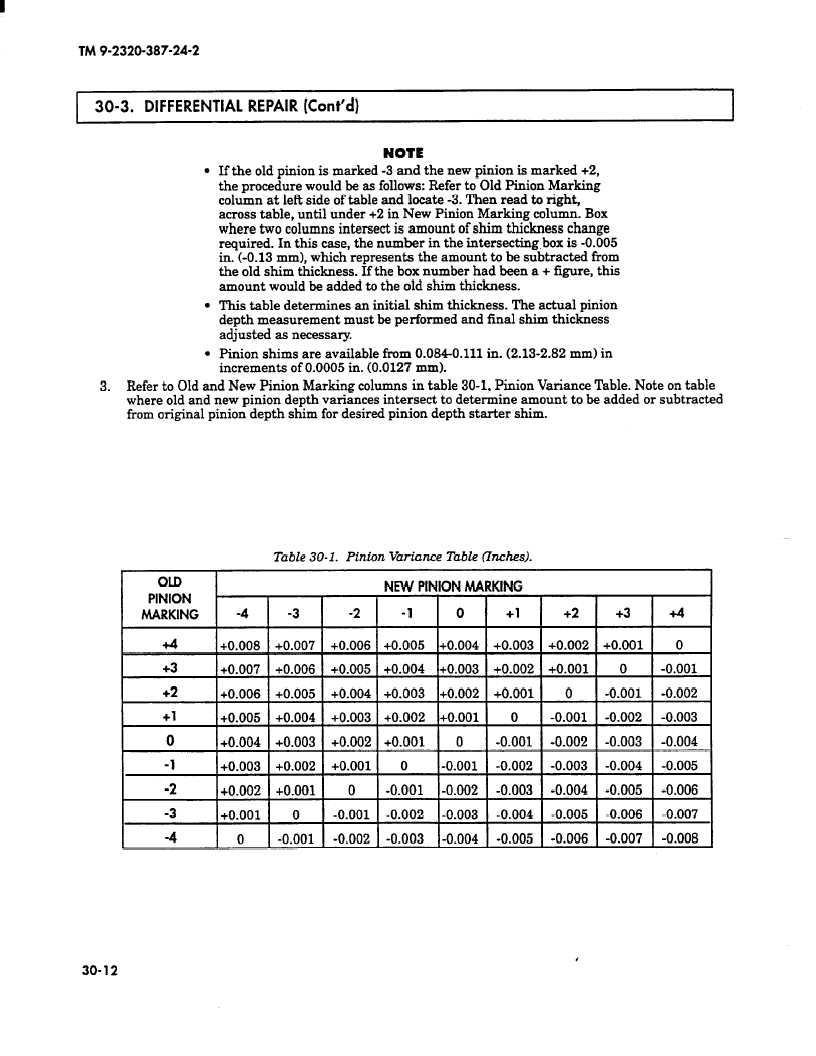

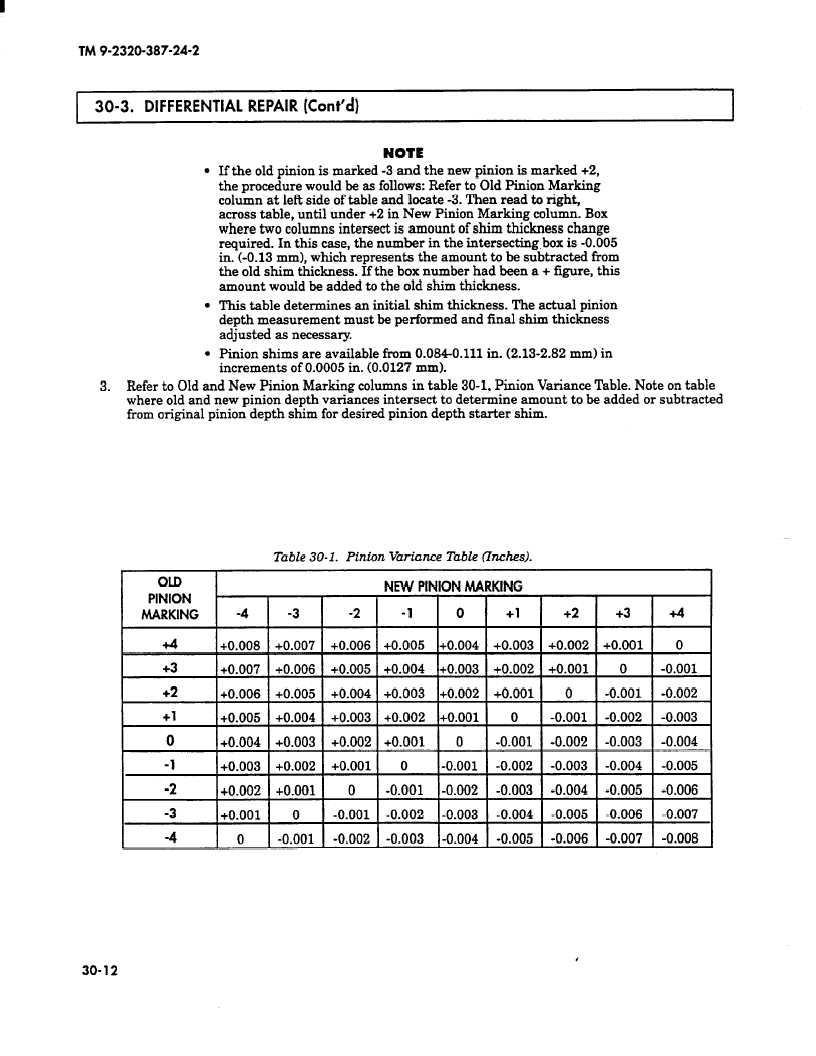

NOTE

l If the old pinion is marked -3 and the new pinion is marked +2,

the procedure would be as follows: Refer to Old Pinion Marking

column at left side of table and locate -3. Then read to right,

across table, until under +2 in New Pinion Marking column. Box

where two columns intersect is amount of shim thickness change

required. In this case, the number in the intersecting.box is -0.005

in. (-0.13 mm), which represents the amount to be subtracted from

the old shim thickness. If the box number had been a + figure, this

amount would be added to the old shim thickness.

l This table determines an initial shim thickness. The actual pinion

depth measurement must be performed and final shim thickness

adjusted as necessary.

l Pinion shims are available from 0.084-0.111 in. (2.13-2.82 mm) in

increments of 0.0005 in. (0.0127 mm).

Refer to Old and New Pinion Marking columns in table 30-1, Pinion Variance Table. Note on table

where old and new pinion depth variances intersect to determine amount to be added or subtracted

from original pinion depth shim for desired pinion depth starter shim.

Table30-1.

Pinti

I

+4

I +0.008 +0.007 +0.006

I

I

+3

+0.007

+0.006

+0.005

+2

+0.006

+0.005

+0.004

+l

+0.005

+0.004

+0.003

0

+0.004

+0.003

+0.002

-1

+0.003 +0.002 +O.OOl

-2

+0.002

+O.OOl

0

I -3

+O.OOl

0

-0.001

I

I

1

I

a

1

0

1

-0.001

1

-0.002

~ -0.003

-0.004

-0.005

-0.006

-0.007

-0.008

n Variance

Table

(Inches).

NEW PINION

MARKING

-1

0

+l

+2

+3

+4

+0.005

+0.004 +0.003 +0.002 +O.OOl

0

+0.004 +0.003 +0.002 +O.OOl

0

-0.001

+0.003

+0.002 +O.OOl

0

-0.001

-0.002

+0.002

+O.OOl

0

-0.001

-0.002

-0.003

+O.OOl

0

-0.001

-0.002

-0.003

-0.004

0

-0.001

-0.002 -0.003 -0.004 -0.005

-0.001

-0.002 -0.003 -0.004 -0.005 -0.006

-0.002 -0.003 -0.004 -0.005 -0.006 -0.007

30-12