Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

ITEM

NO.

INTERVAL

ITEM TO BE

INSPECTED

PROCEDURES

26

Semi-

Arctic

Inspect all fuel lines for loose connec-

Any class III leak.

Annual

Winterization tions, splits, cracks, and bends that

Kit and/or

could cause leaks. Tighten loose connec-

Troop/Cargo tions and replace damaged parts.

Winterization

Kit

27

Semi-

Final Road

Check vehicle for proper operation

Vehicle fails to operate

Annual

Test

and performance.

properly.

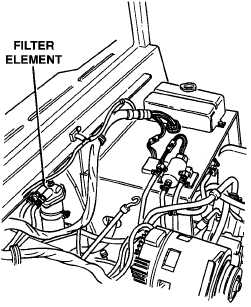

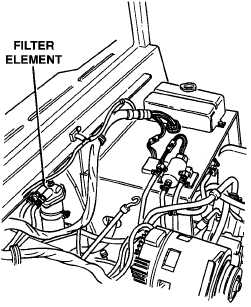

28

Annually

Fuel

Replace filter element every 6,000

System

miles (9,600 km) or annually, which-

ever occurs first. Replace water sepa-

rator element if unserviceable (para.

3-33).

29

Annually

Air-Intake

Test CDR valve (para. 3-9).

System

29.1

Annually

Dust

Visually inspect dust unloader for

Dust unloader missing or

Unloader

presence and for cuts, tears,

has cuts, tears, obstruc-

obstructions, worn areas, enlarged

tions, worn areas,

gap, or if center opening exceeds

enlarged gap, or if center

1/8 in. (3.175 mm).

opening exceeds 1/8 in.

(3.175 mm).

TM 9-2320-280-20-1

Change 1

2-25

NOT FULLY MISSION

CAPABLE IF:

NOTE

If Annual/Biennial Service is being

performed, then Final Road Test will

be completed after last Annual/

Biennial task is complete.