TM 9-2320-387-24-2

28- 19. TRANSMISSION

ASSEMBLY FROM SUBASSEMBLIES

(Cont’d)

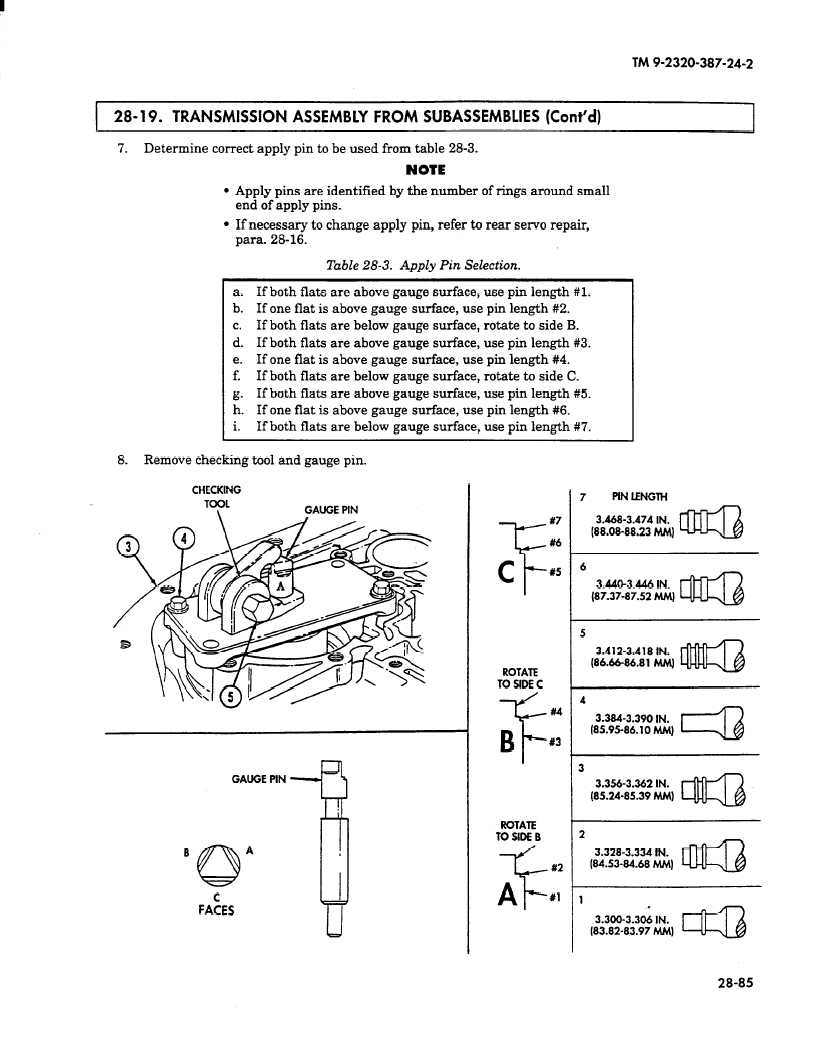

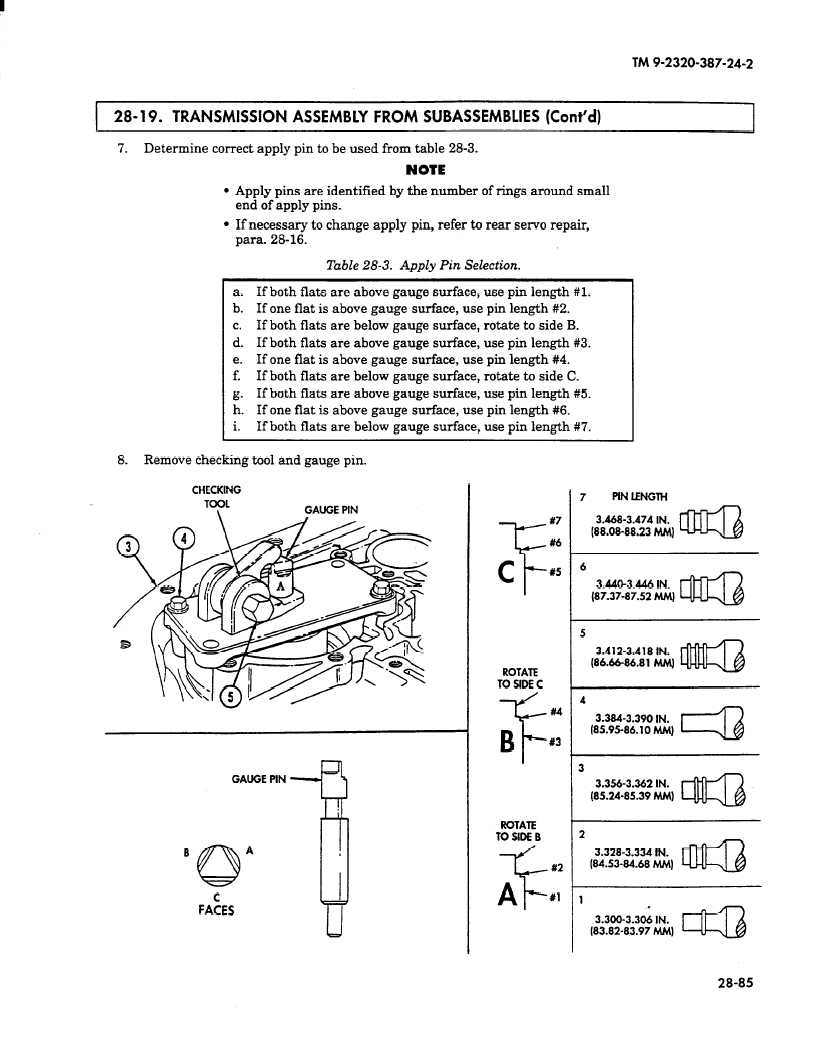

7.

Determine correct apply pin to be used from table 28-3.

NOTE

l Apply pins are identified by the number of rings around small

end of apply pins.

l If necessary to change apply pin, refer to rear servo repair,

para. 28-16.

Table 28-3. Apply Pin Selection.

a. If both flats are above gauge surface, use pin length #l.

b. If one flat is above gauge surface, use pin length #2.

c. If both flats are below gauge surface, rotate to side B.

d. If both flats are above gauge surface, use pin length #3.

e. If one flat is above gauge surface, use pin length #4.

f.

If both flats are below gauge surface, rotate to side C.

g. If both flats are above gauge surface, use pin length #5.

h. If one flat is above gauge surface, use pin length #6.

i.

If both flats are below gauge surface, use pin length #7.

8.

Remove checking tool and gauge pin.

CHECKING

TOOL

\

GAUGE PIN

GAUGE PIN

--if?

B cl A

&ES

ROTATE

TO SlDE C

#4

ROTATE

TO SIDE B

7

PIN LENGTH

3.468-3.474 IN.

(88.08-88.23 MM)

6

3.440-3.446 IN.

(87.37-87.52 MM)

5

3.412-3.418 IN.

(86.66-86.8

1 MM)

4

3.384-3.390

IN.

(85.95-86.10 MM)

3

3.356-3.362 IN.

(85.24-85.39 MM) m

2

3.328-3.334 IN.

(84.53-84.68 MM)

1

.

3.300-3.306 IN.

(83.82-83.97 MM)

28-85