TM 9-2320-387-24-2

1

21-6.

GEARED HUB REPAIR (Cont’d)

1

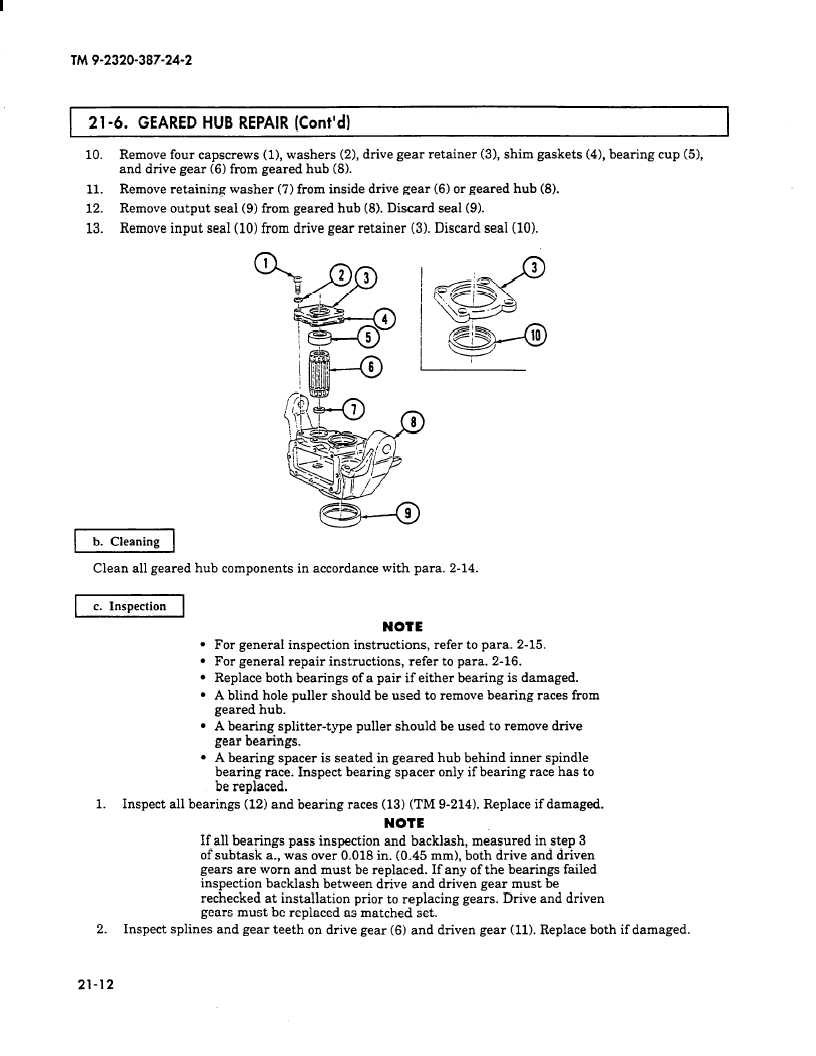

10.

Remove four capscrews (11, washers (21, drive gear retainer (31, shim gaskets (41, bearing cup (51,

and drive gear (6) from geared hub (8).

11.

Remove retaining washer (7) from inside drive gear (6) or geared hub (8).

12.

Remove output seal (9) from geared hub (8). Discard seal (9).

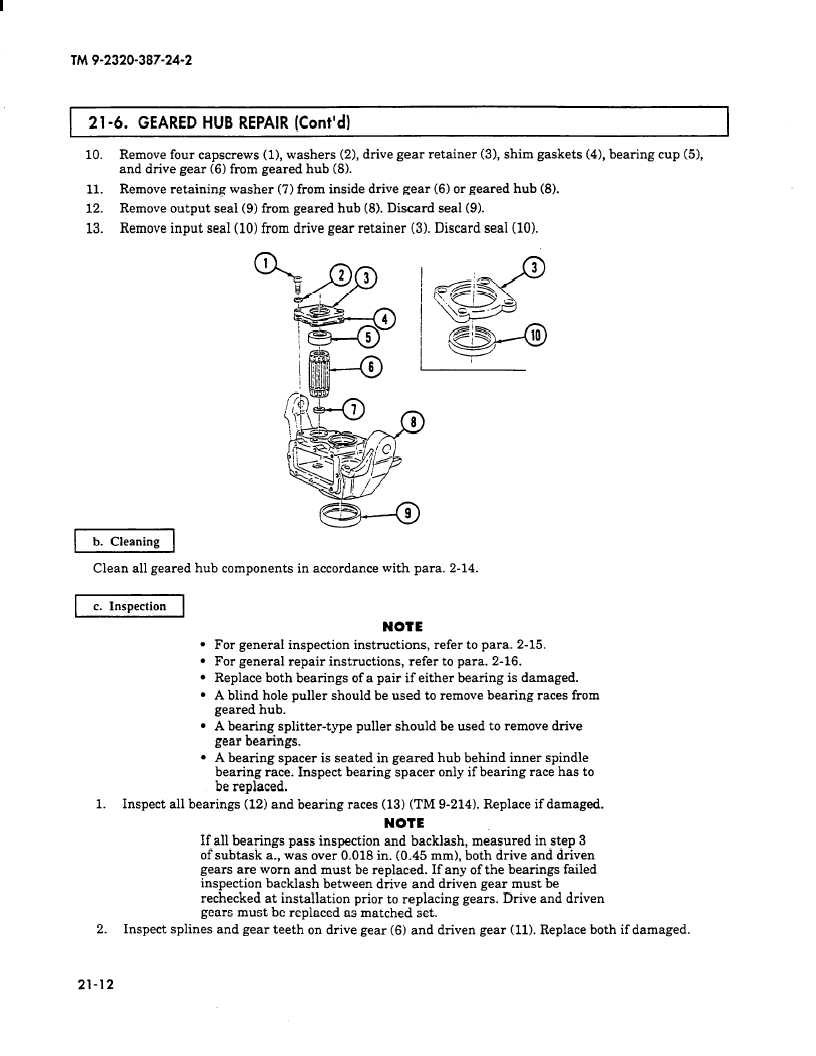

13.

Remove input seal (10) from drive gear retainer (3). Discard seal (101.

b. Cleaning

Clean all geared hub components in accordance with para. 2-14.

c. Inspection

NOTE

For general inspection instructions, refer to para. 2-15.

For general repair instructions, refer to para. 2-16.

Replace both bearings of a pair if either bearing is damaged.

A blind hole puller should be used to remove bearing races from

geared hub.

A bearing splitter-type puller should be used to remove drive

gear bearings.

A bearing spacer is seated in geared hub behind inner spindle

bearing race. Inspect bearing spacer only if bearing race has to

be replaced.

1.

Inspect all bearings (12) and bearing races (13) (TM 9-214). Replace if damaged.

NOTE

If all bearings pass inspection and backlash, measured in step 3

of subtask a., was over 0.018 in. (0.45 mm), both drive and driven

gears are worn and must be replaced. If any of the bearings failed

inspection backlash between drive and driven gear must be

rechecked at installation prior to replacing gears. Drive and driven

gears must be replaced as matched set.

2.

Inspect splines and gear teeth on drive gear (6) and driven gear (11). Replace both if damaged.

21-12