15-28. ENGINE INSTALLATION (Cont’d)

TM 9-2320-387-24-2

15-112

Change 1

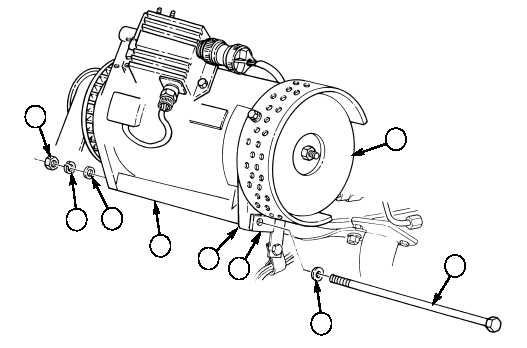

67.

Position alternator (2) on mounting bracket (8) with support bracket (6) on outside of alternator

mounting flange (7) and install washer (4), capscrew (3), washer (4), lockwasher (9), and nut (1).

68.

Install positive cable (14) on stud (17) with washer (13), lockwasher (12), and nut (11). Tighten nut

(11) to 10-15 lb-ft (14-20 N•m).

69.

Install rubber boot (10) over stud (17).

70.

Install ground strap (19) on negative stud (18) with washer (20), lockwasher (21), and nut (22).

Tighten nut (22) to 8-12 lb-ft (11-16 N•m).

NOTE

• Ensure terminals are clean before connections are made.

• Steps 67 through 75 are for the 200-amp dual voltage

alternator. The 400-amp dual voltage alternator procedures are

similar.

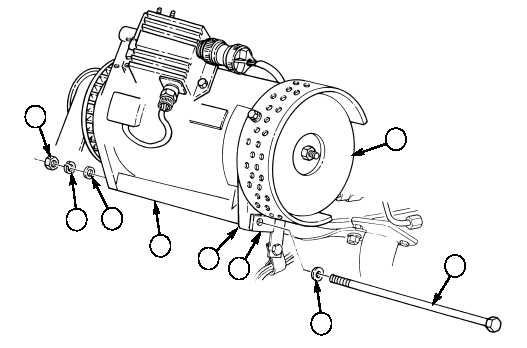

71.

Position 3/8-in. breaker bar or, as appropriate, a 1/2-in. ratchet wrench on belt tensioner (24) and

move tensioner (24) clockwise to allow installation of drivebelt (23).

72.

Feed drivebelt (23) into groove on crankshaft pulley (31), A/C compressor or idler pulley (25),

alternator pulley (28), power steering pump pulley (29), upper idler pulleys (26) and (27), water

pump pulley (30), and tensioner pulley (32). Release belt tensioner (24).

73.

Install lead (43), washer (42), and nut (45) on terminal (41). Tighten nut (45) to 18-22 lb-in.

(2.0-2.5 N•m). Slide rubber boot (44) over terminal (41).

74.

Install washer (33), lead 568 (33.1), and nut (34) on IGN terminal (46). Tighten nut (34) to

23-27 lb-in. (2.6-3.0 N•m). Slide rubber boot (35) over terminal (46).

75.

Install washer (39), lead 2A (38), and nut (37) on AC terminal (40). Tighten nut (37) to

18-22 lb-in. (2.0-2.5 N•m). Slide rubber boot (36) over terminal (40).

1

4

9

8

7

6

4

3

2