TM 9-2320-387-24-2

Change 1

D-84.1

Section II. ILLUSTRATED MANUFACTURING INSTRUCTIONS (Cont'd)

2. Position rope after seizing in a suitable fixture to make a loop, leaving enough rope to wrap around

thimble and enclose in clamp.

3. Thread wire rope through eyelid in hook, insert thimble and close jaws of fixture to enable rope to

conform to groove of thimble.

4. Place one-half of clamp in position and adjust rope accordingly. The seized portion of the wire rope

should equal one rope diameter and protrude entirely beyond the threaded end of the clamp half.

5. Install clamp nut. Holding both threaded halves in position, push the nut into both halves through the

first two threads. Ensure proper alignment of both threaded halves and that there is no cross-

threading.

6. Remove rope, clamp, and thimble while still connected.

7. Hold opposing flats of clamp halves in suitable fixture and properly lubricate exposed threads with

high-viscosity lubricating oil.

8. Using a permanent marker, mark one flat nut to ensure the same opposing flats are checked before

and after tightening the clamp.

9. Using calipers, measure 1/8 in. (3.16 mm) across the flat nut from the bottom and note measurement.

10. Check to ensure clamp halves are properly secured in fixture and tighten with appropriate wrench.

11. Using calipers, again take measurement of the same flat nut as was done before tightening of the nut.

If the increment dilation is between 0.004 in. (.102 mm) and 0.007 in. (.178 mm), clamp is tight.

12. Using arbor press, crimp terminal to opposite end of wire rope.

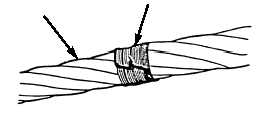

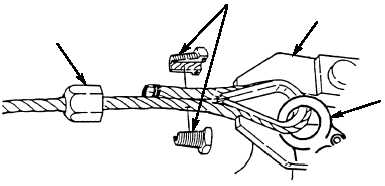

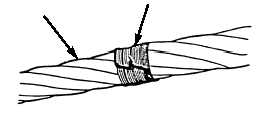

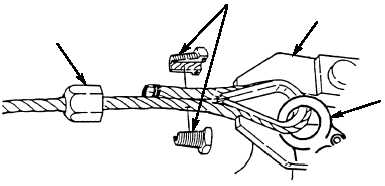

WIRE ROPE

SEIZING

FLAT NUT

CLAMP HALVES

FIXTURE

HOOK