TM 9-2320-387-24-2

33-9. FIBERGLASS REPAIR

a. General. The hood and engine access cover are made of fiberglass (sheet molding compound). Cracks,

splits, or holes may be repaired with a glass-reinforced plastic laminate repair kit, ML-R-19907C, NSN

2090-00-372-6064.

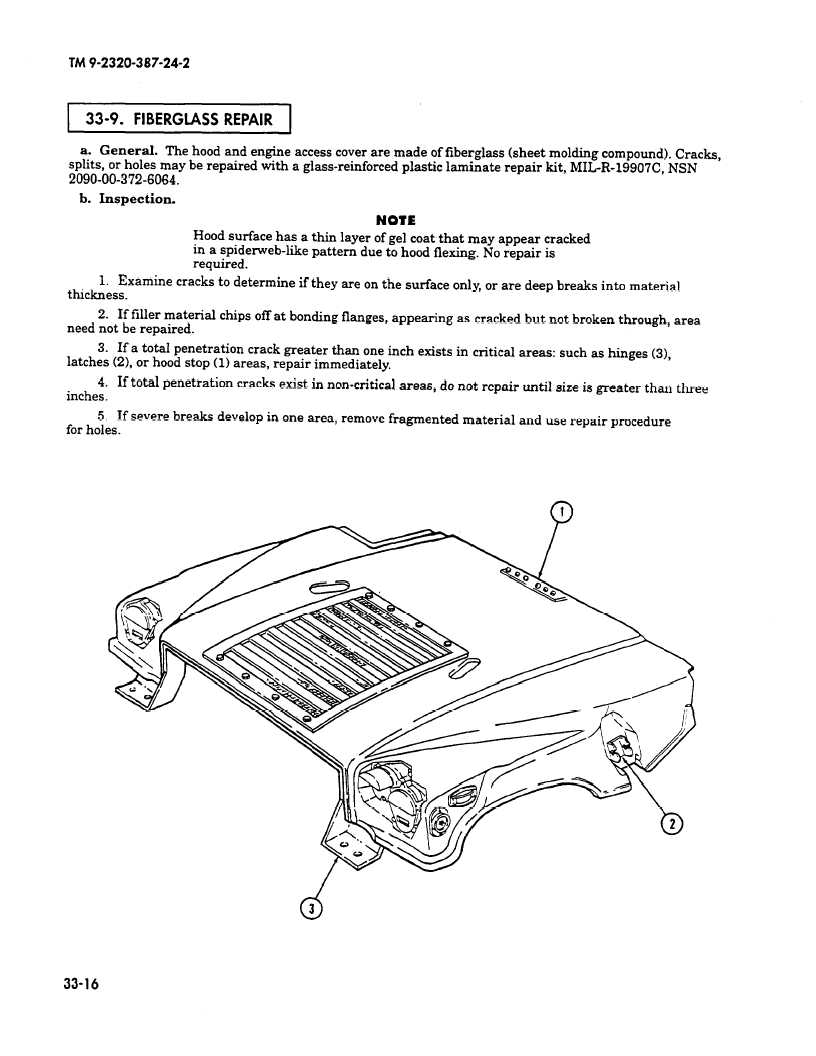

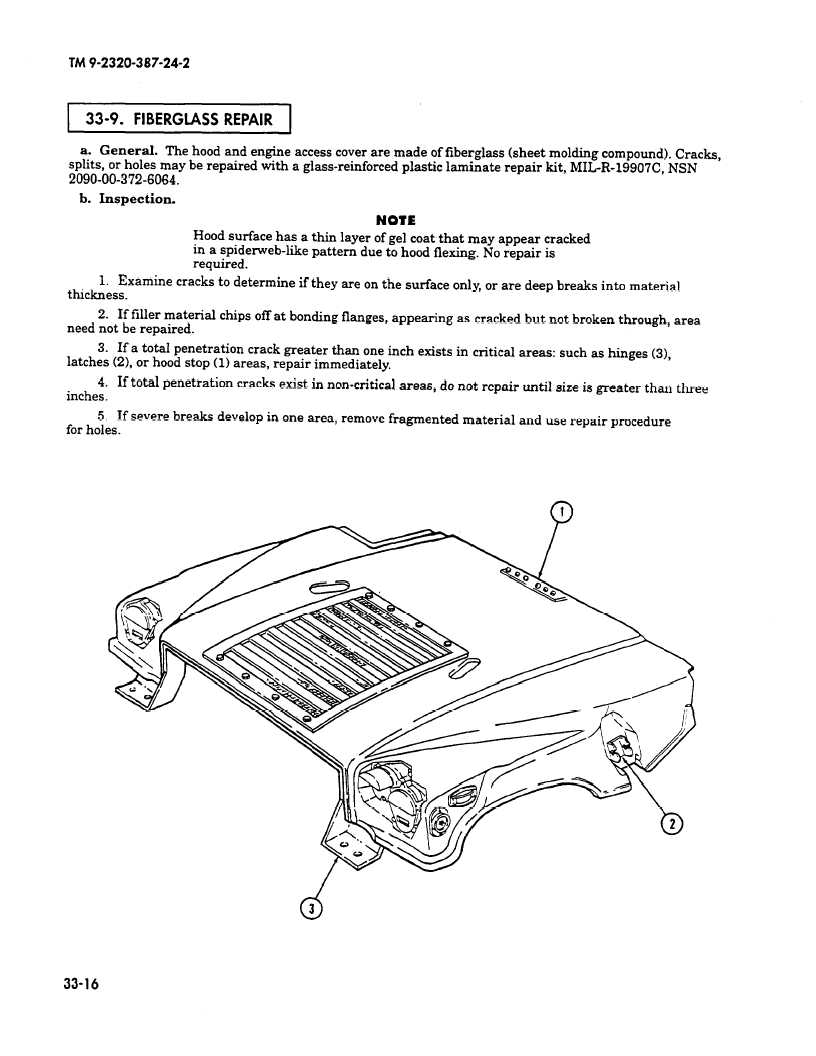

b. Inspection.

NOTE

Hood surface has a thin layer of gel coat that may appear cracked

in a spider-web-like pattern due to hood flexing. No repair is

required.

1. Examine cracks to determine if they are on the surface only, or are deep breaks into material

thickness.

2. If filler material chips off at bonding flanges, appearing as cracked but not broken through, area

need not be repaired.

3. If a total penetration crack greater than one inch exists in critical areas: such as hinges (31,

latches (21, or hood stop (1) areas, repair immediately.

4.

inches.

If total penetration cracks exist in non-critical areas, do not repair until size is greater than three

5. If severe breaks develop in one area, remove fragmented material and use repair procedure

for holes.

33-16