TM 9-2320-387-24-l

1 8-4. RADIAL TIRE, WHEEL, AND RUBBER RUNFLAT MAINTENANCE

(Cont’d)

1

17.

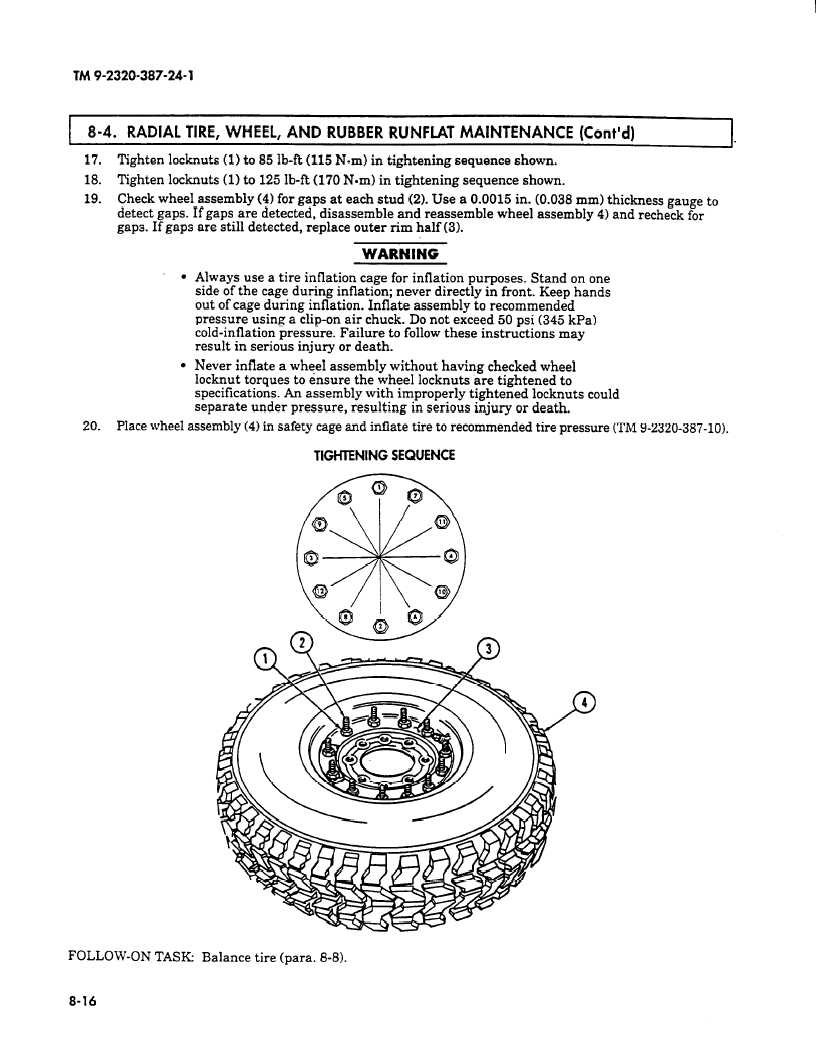

Tighten locknuts (1) to 85 lb-ft (115 Nom) in tightening sequence shown.

18.

Tighten locknuts (1) to 125 lb& (170 N-m) in tightening sequence shown.

19.

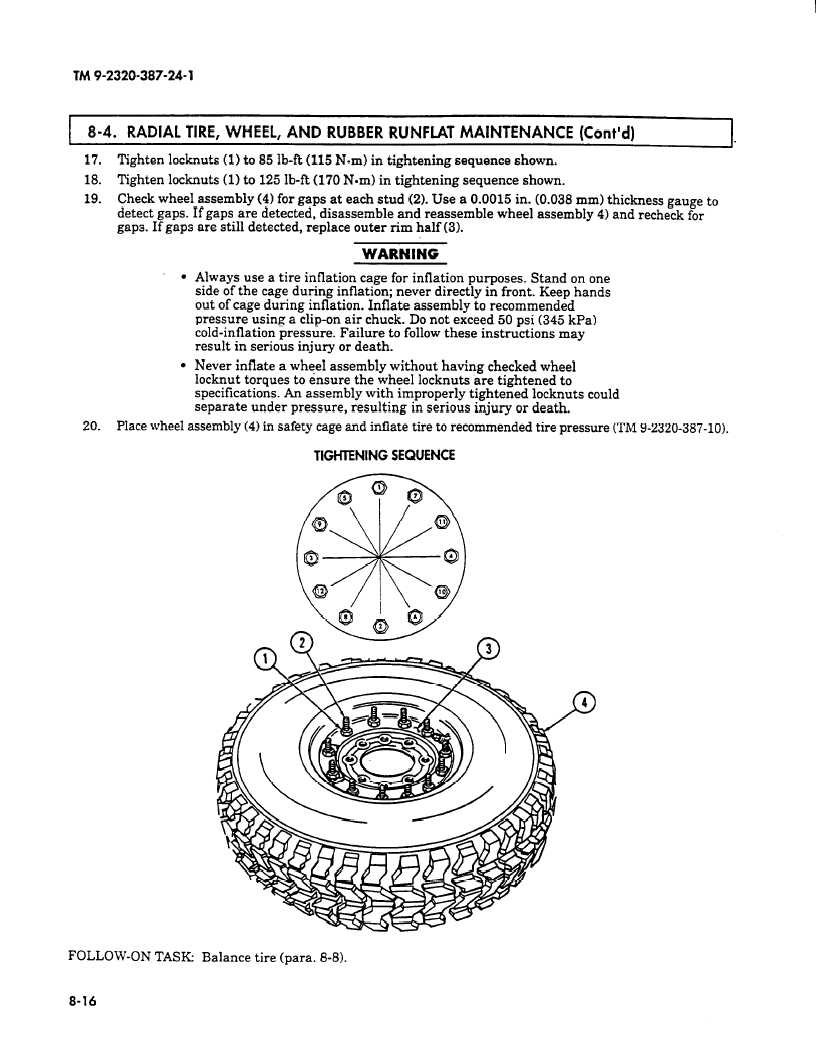

Check wheel assembly (41 for gaps at each stud (21. Use a 0.0015 in. (0.038 mm) thickness gauge to

detect gaps. If gaps are detected, disassemble and reassemble wheel assembly 4) and recheck for

gaps. If gaps are still detected, replace outer rim half (3).

WARNING

l Always use a tire inflation cage for inflation purposes. Stand on one

side of the cage during inflation; never directly in front. Keep hands

out of cage during inflation. Inflate assembly to recommended

pressure using a clip-on air chuck. Do not exceed 50 psi (345 kPa)

cold-inflation pressure. Failure to follow these instructions may

result in serious injury or death.

l Never inflate a wheel assembly without having checked wheel

locknut torques to ensure the wheel locknuts are tightened to

specifications. An assembly with improperly tightened locknuts could

separate under pressure, resulting in serious injury or death.

20.

Place wheel assembly (41 in safety cage and inflate tire to recommended tire pressure (TM 9-2320-387-10).

TIGHTENING SEQUENCE

FOLLOW-ON TASK Balance tire (para. 8-8).

8-16