8-4.1. BIAS TIRE, WHEEL, AND RUBBER RUNFLAT MAINTENANCE (Cont'd)

d. Assembly

.WARNING.

• Never use tubes in wheel assemblies. Use of a tube defeats

built-in safety features, and could allow the wheel to come apart

under pressure, resulting in serious injury or death.

• Use only replacement parts specified in TM 9-2320-280-24P.

Wheels assembled with components which do not meet

specifications could cause the assembly to separate under

pressure, resulting in serious injury or death.

• Do not use runflat compressor if compressor strap is frayed or

damaged. Ensure runflat is free of grease and runflat

compressor strap is centered on runflat. Failure to do so could

cause injury to personnel.

• Any oil on runflat compressor belt could result in personnel injury

or damage to equipment. Wipe any oil off from belt or handle.

NOTE

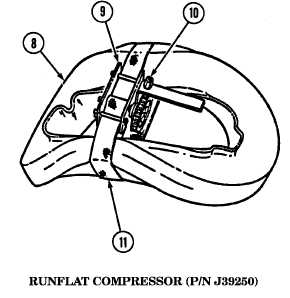

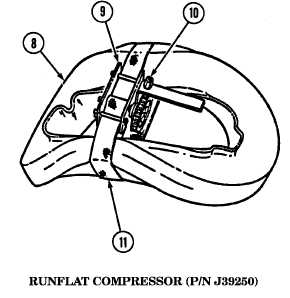

Perform steps 1 and 2 when using runflat compressor P/N J39250.

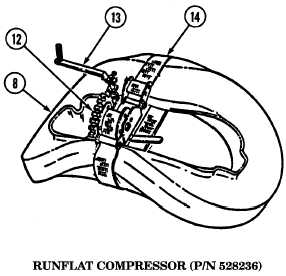

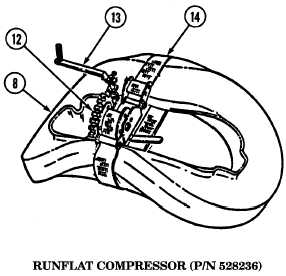

Perform steps 3 and 4 when using runflat compressor P/N 528236.

1.

Position runflat compressor (9) on runflat (8) so that runflat compressor hex drive (10) is facing up

and strap (11) is centered around runflat (8).

NOTE

Compress runflat by rotating hex drive in either direction. Rotate

hex drive opposite to loosen.

2.

Using runflat compressor (9), compress runflat (8).

3.

Position runflat compressor (12) on an outer edge of runflat (8) with handle assembly (13) facing up

and strap (14) centered around runflat (8).

NOTE

Compress runflat by rotating the handle assembly in a clockwise

direction. Rotate handle assembly counterclockwise to loosen.

4.

Using runflat compressor (12), compress runflat (8).

TM 9-2320-280-20-2

Change 2

8-14.7