.WARNING.

O-ring sealing surfaces and pressure relief grooves must be kept

clean and free of rust and dirt. Failure to do so could cause the

wheel assembly to separate under pressure, causing serious injury

or death.

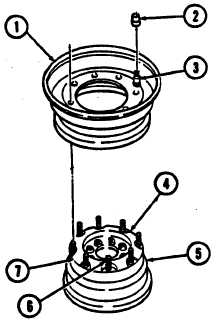

7.

Using wire brush, clean studs (6). Clean all dirt and foreign material from rim halves (1) and (4)

with soap and water and allow to air dry. Ensure O-ring sealing surfaces (7) and pressure relief

grooves (5) on rim halves (1) and (4) are smooth and clean.

8.

Inspect rim halves (1) and (4) for cracks, bent sealing surfaces (7), or oversized mounting holes.

Replace rim halves (1) or (4) if cracked, bent, or if mounting holes are oversized.

.WARNING.

Never use wheel assemblies with studs which are damaged, loose,

or have damaged threads. Damaged studs can cause improper

assembly, which could cause individual fasteners to fail. Any of

these situations could cause serious injury or death.

9.

Inspect inner rim half (4) for cracked, broken, rusted, pitted, bent, or loose studs (6).

10.

Inspect studs (6) for damaged or deformed threads. Replace studs (6) if threads are damaged or if

studs (6) are damaged or loose (para. 8-8).

11.

Inspect valve core (2) for cracks or deterioration. Replace valve core (2) if cracked or deteriorated.

12.

Inspect valve stem (3) for cracks or deterioration. Replace valve stem (3) if cracked or deteriorated.

8-4.1. BIAS TIRE, WHEEL, AND RUBBER RUNFLAT MAINTENANCE(Cont'd)

Refer to TM 9-2610-200-24 for maintenance and repair of tires.

c. Repair

TM 9-2320-280-20-2

8-14.6

Change 2