6-13. GEARED HUB SPINDLE SEAL REPLACEMENT(Cont'd)

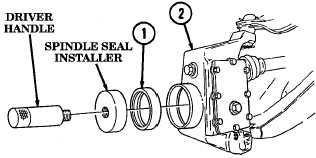

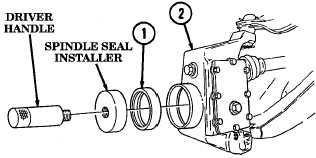

1.

Using driver handle and spindle seal installer, install spindle seal (1) in geared hub (2).

2.

Coat spindle seal (1) with lubricating oil.

3.

Install spacer (3) and spindle (4) in geared hub (2).

4.

Apply grease to face of retaining nut (9).

NOTE

• If four-slotted retaining nut TN-07 is present, it is recommended to

replace it with eight-slotted retaining nut 12342680.

• Ensure lip of spacer faces the bearing for a proper fit.

5.

Install spacer (5), bearing (6), keyed washer (7), lockwasher (8), and retaining nut (9) on spindle (4).

6.

Using retaining nut wrench, tighten retaining nut (9) to 35-45 lb-ft (47-61 N•m).

7.

Rotate spindle (4) five full rotations clockwise and five full rotations counter clockwise to properly

seat bearings.

8.

Loosen retaining nut (9) until it is finger tight, then retighten nut to 23-27 lb-ft (31-37 N•m).

WARNING

Ensure locktab on lockwasher is bent completely into slot on retaining

nut. Eight-slotted retaining nut provides additional security by

enabling two locktabs on lockwasher to be bent into slots on retaining

nut. Failure to do this may cause injury to personnel or damage to

equipment.

NOTE

• For new configuration, two locktabs on lockwasher must be bent into

slots on retaining nut.

• It may be necessary to slightly loosen or tighten retaining nut to gain

proper alignment with locktabs.

9.

Determine which locktab (10) on lockwasher (8) aligns with slot (11) in retaining nut (9). Bend

locktab (10) into slot (11) on retaining nut (9).

NOTE

Immediately install steering arm cover after application of sealant.

10.

Clean sealing surfaces on geared hub (2) and steering arm cover (14). Apply anaerobic sealant to

steering arm cover (14) and install steering arm cover (14) on geared hub (2).

11.

Apply sealing compound to threads of capscrews (12) and install steering arm cover (14) on geared

hub (2) with four washers (13) and capscrews (12). Tighten capscrews (12) to 65 lb-ft (88 N•m).

12.

Remove fill plug (15) and washer (16) from geared hub (2).

13.

Fill geared hub (2) to proper oil level (para. 2-11).

14.

Install washer (16) and fill plug (15) on geared hub (2). Tighten fill plug (15) to 8-13 lb-ft (11-18 N•m).

b. Installation

TM 9-2320-280-20-2

6-36

Change 2