TM 9-2320-387-24-l

REFERENCE INFORMATION

ENGINE LUBRICATION

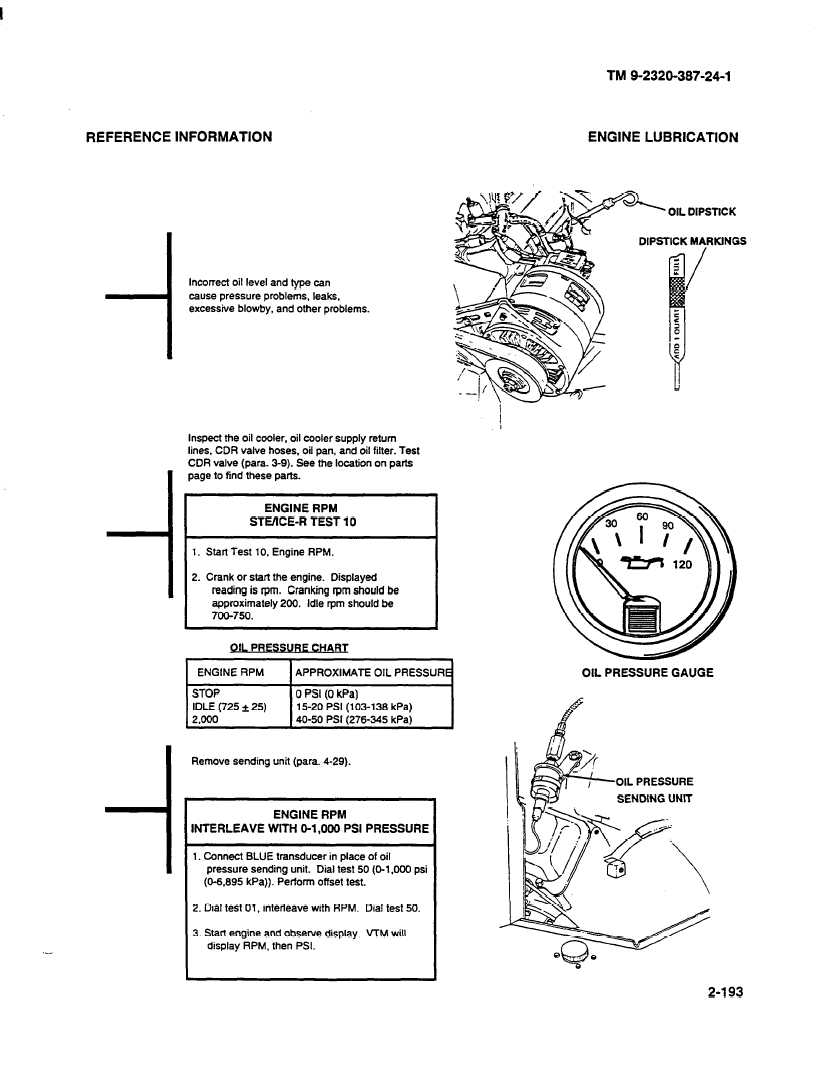

Incorrect oil level and type can

cause pressure problems, leaks,

excessive blowby. and other problems.

Inspect the oil cooler, oil cooler supply return

lines, CDR valve hoses, oil pan, and oil filter. Test

CDR valve (para. 3-9). See the location on parts

page to find these parts.

ENGINE RPM

STMCE-R TEST 10

1. Start Test 10, Engine RPM.

2. Crank or start the engine.

Displayed

reading is mm. Cranking rpm should be

approximately

200. Idle rpm should be

700-750.

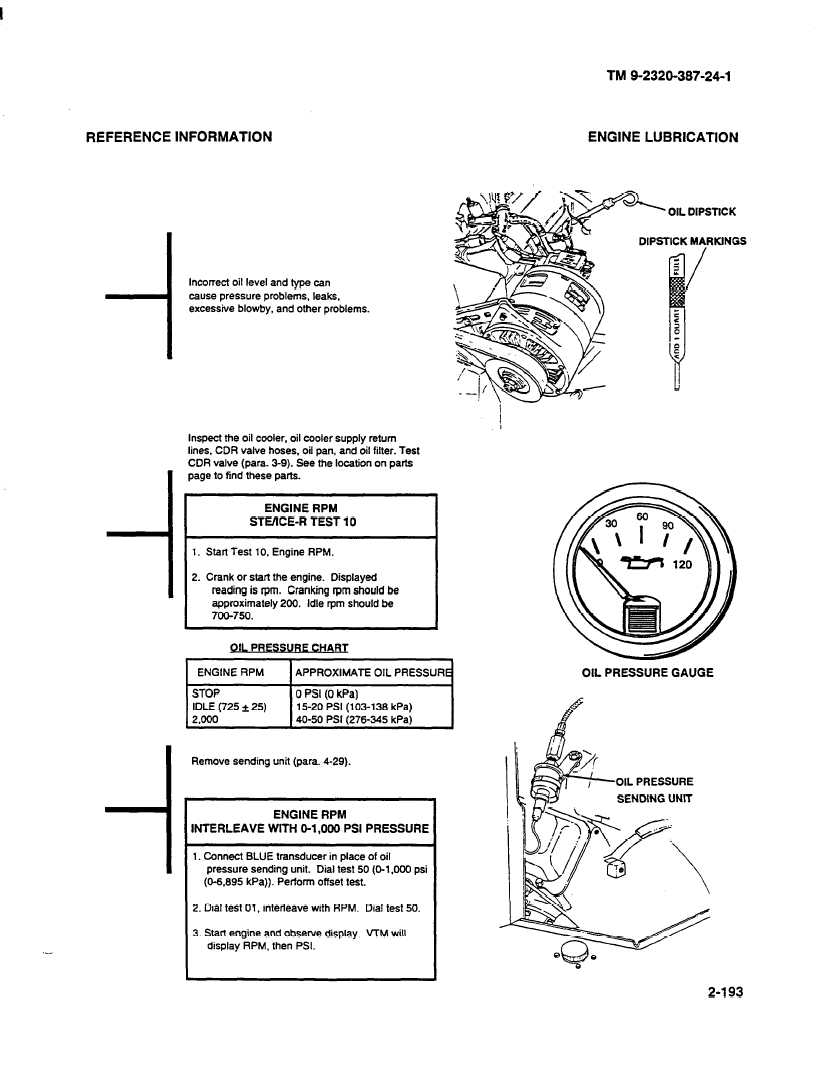

Remove sending unit (para. 4-29).

ENGINE RPM

INTERLEAVE WITH O-l,000 PSI PRESSURE

I. Connect BLUE transducer in place of oil

pressure sending unit. Dial test 50 (O-l ,000 psi

(O-5.995 kPa)). Perform offset test.

2. Dial test 01, interleave with RPM. Dial test 50.

3. Stan engine and observe display.

VIM will

display RPM, then PSI.

OIL PRESSURE GAUGE

OIL PRESSURE

SENDING UNlT

2-193