CAUTION

TM 9-2320-280-20-3

11-202. COMPRESSOR BELT MAINTENANCE

This task covers:

a. Removal

c. Adjustment

b. Installation

INITIAL SETUP:

Applicable Models

M997, M997A1, M997A2

Tools

General mechanic’s tool kit:

automotive (Appendix B, Item 1)

Special Tools

Belt tension gauge (Appendix B, Item 67)

Crowfoot, 14 mm (Appendix B, Item 152)

Personnel Required

One mechanic

One assistant

Manual References

TM 9-2320-280-24P

Equipment Condition

l Engine right splash shield removed (para. 10-20).

l Engine access cover removed (para. 10-15).

l Serpentine drivebelt removed (“A2” series only)

(para. 3-83).

1. Loosen two capscrews (10) from compressor (11) and support bracket (12).

2. Loosen two nuts (1) and capscrew (7) from adjusting bracket (5) and mounting ears (6).

3. Loosen nut (2) on adjusting bracket (5) and timing cover bolt (3), and push compressor (11) toward

timing chain cover (4) to loosen belt (9).

4. Disconnect fan drive hose (15) from fan drive assembly (17).

5. Remove belt (9) from compressor pulley (8), water pump pulley (14), crankshaft pulley (16), and over

fan blades (13).

b. Installation

Install belt (9) over fan blades (13) and place belt (9) on crankshaft pulley (16), water pump pulley (14),

and compressor pulley (8).

NOTE

If belt was replaced, go to step 2.

1. Perform Removal, steps a.1 through a.4.

DO not pry against compressor housing with pry bar when

adjusting belt tension. Compressor may be damaged.

2. Pull compressor (11) away from timing chain cover (4) and position pry bar between rear mounting

ear (6) and support bracket (12) to adjust belt tension.

3. Using belt tension gauge, check belt (9) for proper tension (refer to table 11-1).

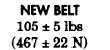

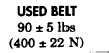

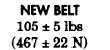

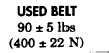

Table 11-1. Compressor Belt Tension Requirements

NOTE

A “used” belt iS one that has run at least fifteen

minutes or fifteen miles (24 kilometers).

11-306