7-12. SERVICE BRAKE CALIPER MAINTENANCE (Cont'd)

Change 2

7-27

TM 9-2320-280-20-2

8.

Inspect rotor (3) for heat cracks, discoloration, pitting, or scoring. Replace rotor (3) if cracked, pitted,

or scored (para. 7-19).

NOTE

• Replace brake pads in sets only.

• Replace brake pads if thickness is less than 3/16 in. (4.8 mm)

and operation in wet and muddy conditions is expected.

9.

Inspect brake pads (2) for glazing, oil saturation, or wear. If glazed, oil satruated, or if brake pad

thickness is less than 1/8 in. (3.2 mm), replace both pads (2) and pads from opposite caliper

(para. 7-11).

c. Installation

WARNING

Ensure brake pads are installed with linings facing rotor. Failure

to do this may cause injury to personnel or damage to equipment.

1.

Install brake pads (2) on adapter (4).

NOTE

Perform step 2 only if yoke locating pins were replaced.

2.

Apply sealing compound to threads of locating pins (8) and install locating pins (8) in yoke (5).

Tighten locating pins (8) to 25-35 lb-ft (34-47 N•m).

3.

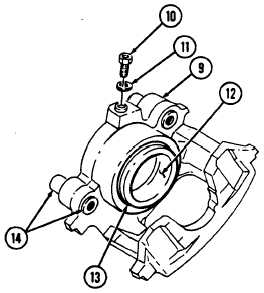

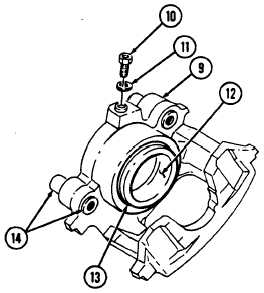

Install caliper (9) on yoke (5).

NOTE

When installing caliper, use a “C” clamp and a block of wood to

bottom out piston in caliper if needed.

4.

Apply sealing compound to tapped holes of adapter (4). Using crowfoot, install yoke (5) and caliper (9)

to adapter (4) with two washers (6) and capscrews (7). Tighten two capscrews (7) to 30-40 lb-ft

(41-54 N•m).

5.

Install copper washer (11) and coupling (10) on caliper (9).

6.

Connect brake line (1) to coupling (10).

FOLLOW-ON TASKS • Bleed brake system (para. 7-10).

• Install brake protection guards (para. 7-8.1) (M998A2 vehicles only).