TM 9-2320-280-20-1

REFERENCE INFORMATION

Change 1 2-473

STEERING SYSTEM

Do not loosen slotted nut to install cotter pin. Loosening the nut

may result in damage to the equipment.

To check for proper operation of ball joints:

(i) Chock rear wheels front and back.

(ii) Raise front wheels about two inches off the ground and

support on a jack stand.

(a)Lower ball joints.

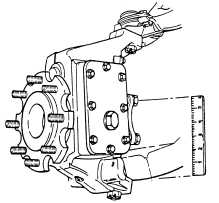

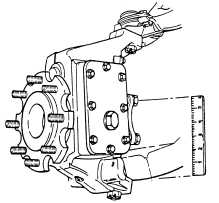

(iii) Mark a line across the head of the top bolt holding the steering

arm cover. Make sure the mark is parallel to the lower control

arm.

(iv) Put a prybar between the cover control arm and geared hub.

(v) Set a 6-inch ruler upright between the lower control arm and the

marked screw.

(vi) Push down the prybar to try to move the hub.

(vii) Measure movement in the hub assembly. If movement is more

than 1/8 inch (3 mm), replace lower ball joint (refer to para. 6-27).

(b) Upper ball joints.

(viii) Grasp top of tire and attempt to move it in and out.

(ix) Measure any movement at top outer edge of tire. Replace upper ball

joints if tire movement is 3/8 inch (10 mm) or more (refer to para. 6-26).

Check for looseness in idler arm and pitman

arm, refer to (para. 8-18 and 8-14). For

replacing center link refer to (para. 8-15). For

replacing tie rods refer to (para. 8-17).

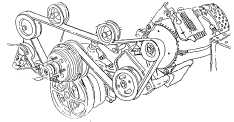

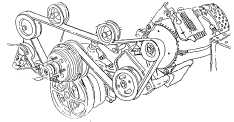

For adjusting the drivebelt tension, refer to (para. 3-82,

all except M1123 and "A2" vehicles), and replacing

the pulley, refer to (para 8-24).

CAUTION

M1123 and "A2"

CONFIGURATION